Like many other technology-minded people, I've watched the saga of the Juicero $400 (down from $700) juice bag squeezer with amusement. buying a cup of juice in a bag for $5 seems like a bad business plan (and many others have already discussed that). I'm more fascinated with the juicero machine itself. AvE did a thorough teardown of the machine, so watch his video for the gory details. In short, the insides of the machine are a thing of beauty, and much too expensive for getting people hooked on a $35 a week juice subscription.

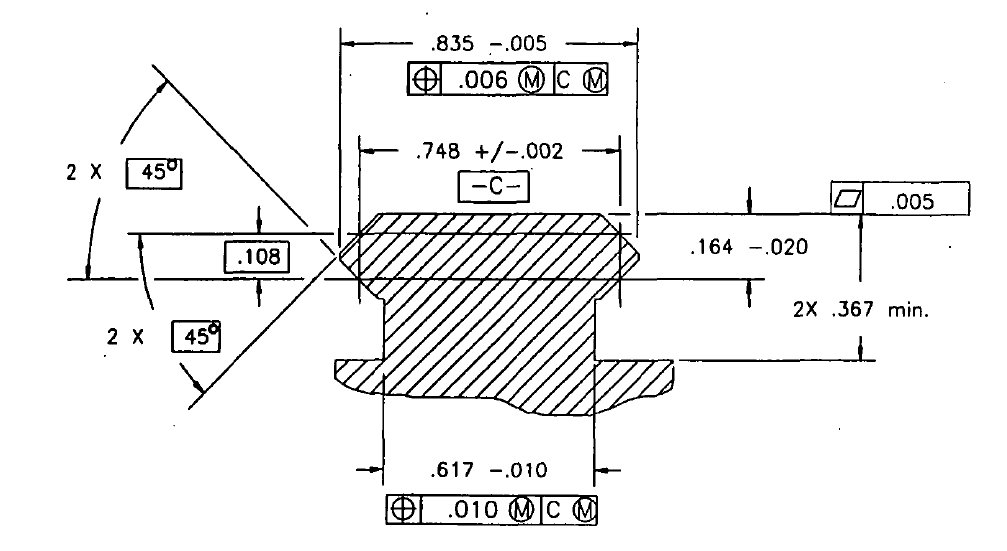

Ben Einstein at Bolt.io also did a detailed teardown of the Juicero, again pointing out how beautiful and totally over-engineered this machine is. He estimates the juice pack is seeing 64psi load in order to get the juice out.

Part of the failure of this whole endeavor is that the machine was so damned expensive! This was an attempt at a "razor and blades" model. Razor and blades is used many places where there's a consumable component; K-cup coffeemakers (allegedly the inspiration for the Juicero), actual shaving razors, computer printers, old polaroid cameras, some video game systems. The whole premise is that you give away the razor, or sell the coffeemaker (or printer) at a heavy loss to get people to then buy the very profitable blades (or printer ink) forever.

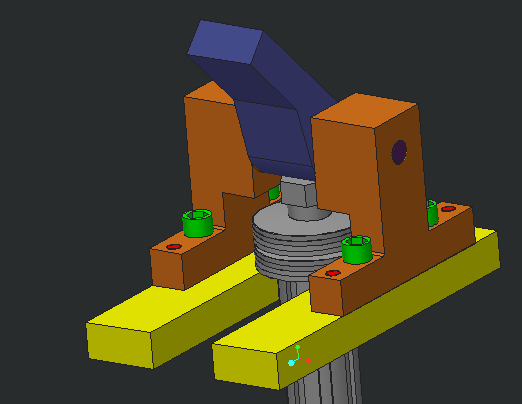

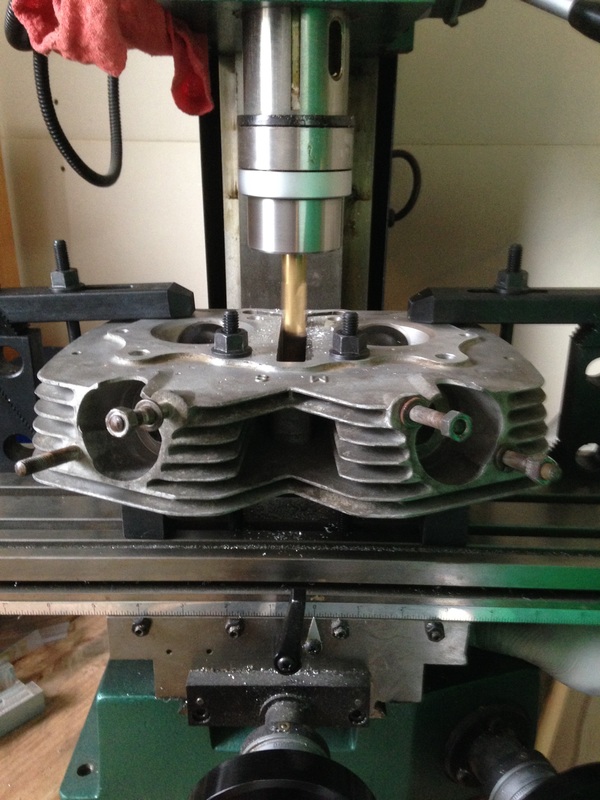

But if you make the machine too expensive, this doesn't work. And this thing is PRICEY! So many CNC-machined components, massive gears, thrust bearings, tapered roller bearings, dowel pins, etc. All of these things are wonderful and expensive. These are how you build one juicer, for a lab, to test juice bag production variability. To see this sort of stuff in a high-volume production item...yeesh. Apple gets away with this in their laptops because it's an aesthetic they're going for, and they're recycling their own super-machinable castable alloy of aluminum to bring it down from "totally bonkers expensive" to merely "high end".

The marketing of the Juicero fixated on how strong the machine was ("Able to lift two Teslas"). Is this necessary? For some historical background, when HP first went all-in on cheapo printers (to get the printers as cheap as possible to start consumers buying ink), one of its leaders stood on an older HP printer and said "The fact that this printer can hold me up means it's too expensive". The Juicero is

To get to why the Juicero provides several tons of crushing force, we need to step back and take a hard look at what the machine is supposed to do.

This is where the designers went wrong. Remember, the goal is to get the juice out of the bag. A 330VDC motor running through a reduction geartrain to a massive Acme screw to put 4 tons of force onto a bag of juice, plus another massive plate to react the 4 tons of force on the other side, all adds up to brute force and ignorance. Very forceful brutality, and beautiful, blissful ignorance.

How else might this have been approached, in a clever way?

But if you make the machine too expensive, this doesn't work. And this thing is PRICEY! So many CNC-machined components, massive gears, thrust bearings, tapered roller bearings, dowel pins, etc. All of these things are wonderful and expensive. These are how you build one juicer, for a lab, to test juice bag production variability. To see this sort of stuff in a high-volume production item...yeesh. Apple gets away with this in their laptops because it's an aesthetic they're going for, and they're recycling their own super-machinable castable alloy of aluminum to bring it down from "totally bonkers expensive" to merely "high end".

The marketing of the Juicero fixated on how strong the machine was ("Able to lift two Teslas"). Is this necessary? For some historical background, when HP first went all-in on cheapo printers (to get the printers as cheap as possible to start consumers buying ink), one of its leaders stood on an older HP printer and said "The fact that this printer can hold me up means it's too expensive". The Juicero is

To get to why the Juicero provides several tons of crushing force, we need to step back and take a hard look at what the machine is supposed to do.

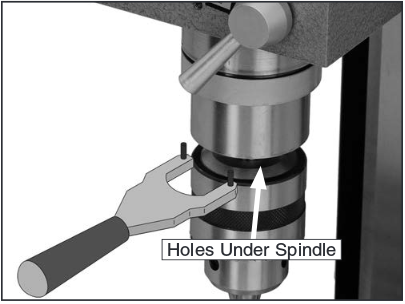

- To crush a juice bag? No. See AvE's video above of a normal human squeezing juice out of the bag by hand.

- To get the juice out of the bag? Yes!

- To get the juice out of the bag in a "reasonable" amount of time? Very Yes.

This is where the designers went wrong. Remember, the goal is to get the juice out of the bag. A 330VDC motor running through a reduction geartrain to a massive Acme screw to put 4 tons of force onto a bag of juice, plus another massive plate to react the 4 tons of force on the other side, all adds up to brute force and ignorance. Very forceful brutality, and beautiful, blissful ignorance.

How else might this have been approached, in a clever way?

- Don't offer a machine at all, and have the customers squeeze the bags themselves. This has been shown to work in videos all over youtube. Redesign the bags if necessary to make them even easier to squeeze. After all, the bags are where the money is. Often the best design is not to design anything.

- Make a toothpaste squeezer (which is what AvE suggests in his video). At this scale, you could call it a clothes-wringer, which was a mature technology in 1905. The level of complexity goes way down. Again, the bags could be redesigned to work in a clothes-wringer, like adding barcodes to the bags so the machine can "see" how close it is to the end of the bag.

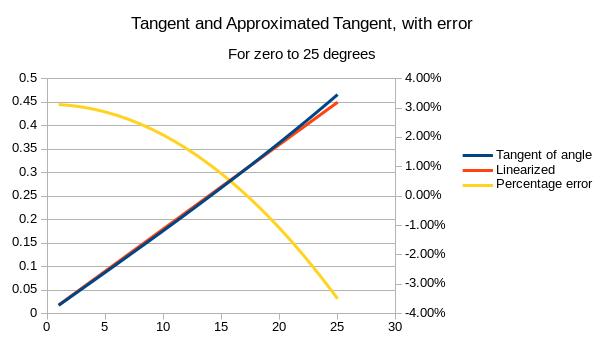

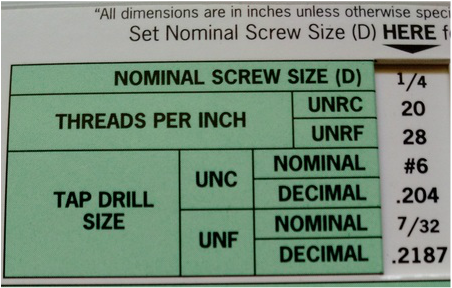

- Use a miniature hydraulic pump to squeeze a water bladder at 64psi against the bag. A tiny peristaltic pump (like what's inside the water flosser in your bathroom) can get to 64psi with no sweat. "But what about the 4 tons of resultant force, how are we handling that?". Build the machine to be cylindrical and then you're just talking about a pipe, which can handle 64psi very efficiently.

- Or as a variation, if 40psi (municipal line pressure) would get enough squeeze, make a fitting to attach a hose for the water bladder straight to the sink and just turn on the sink.

RSS Feed

RSS Feed