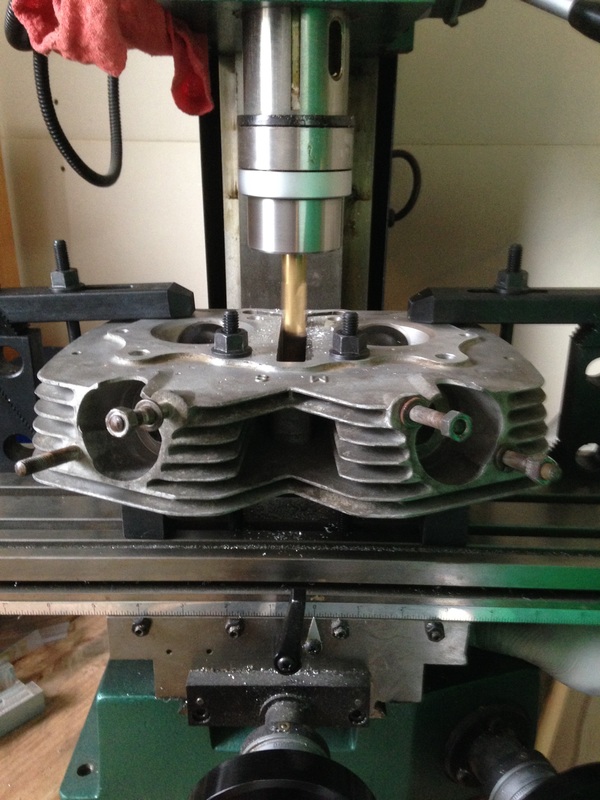

My brother had a Honda CB-350 motorcycle, which he was in the process of restoring. He got a new timing chain tensioner for the overhead cams, but the original timing chain slot in the engine head wasn't wide enough. That's where I came in. We fixtured the head on the mill, which was very simple, if not very easy.

I zeroed the X-axis leadscrew, came over .042, widened the slot .800 deep, then locked the X-travel, took up the backlash, rezeroed the leadscrew, and came backward .109 to finish the job. The tensioner fit perfectly, and the bike's running today as far as I know.

RSS Feed

RSS Feed