I recently helped my lovely wife install a new radio into her car. Taking the old radio out involves some brute force and ignorance, greatly aided by the Master Sheet that Crutchfield emails along with the radio. For some reason, every OEM radio I've seen has an extra screw that serves only to complicate removal. I'd say this is an anti-theft feature, but who steals the crappy stock radio?

The most fun part of installing a new radio is soldering the new radio's plug to the adapter that comes with the install kit. The radio manual helpfully suggests splicing into the car's wiring harness, which is insane.

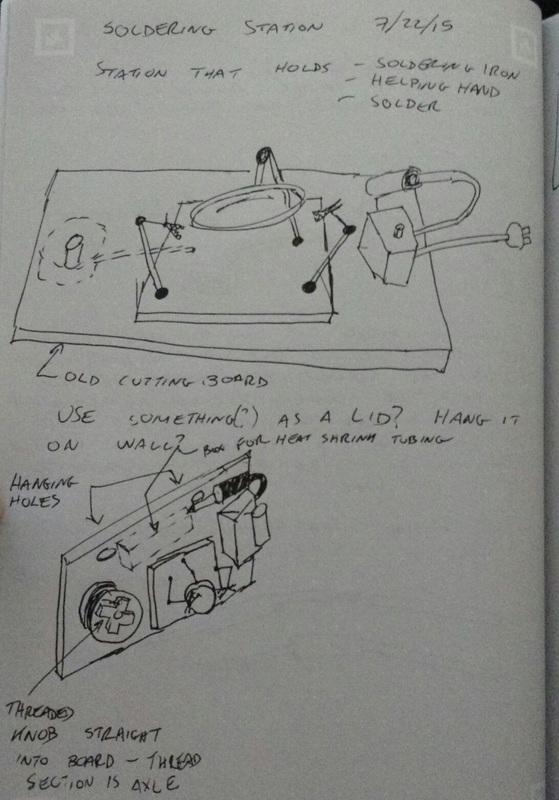

What makes soldering such a pain is having to dig out the soldering iron, and solder (stored in different places, of course) and then find a flat surface to do the soldering.

The most fun part of installing a new radio is soldering the new radio's plug to the adapter that comes with the install kit. The radio manual helpfully suggests splicing into the car's wiring harness, which is insane.

What makes soldering such a pain is having to dig out the soldering iron, and solder (stored in different places, of course) and then find a flat surface to do the soldering.

I took a scrap piece of MDF board (from a super nice knockdown desk) and stuck in a threaded insert, then used a threaded knob to hold on a roll of solder. The actual soldering iron is held stationary using a bunch of wood screws and some zip ties. We'll see how well the zip ties last, but if they're good enough for auto repair they should be dandy in a silly solder board. The final touch is a scrap piece of plywood and part of a paint stir stick to keep the cords from flopping around getting broken.

I still need to add a helping hand and maybe a spot for shrink tubing.

RSS Feed

RSS Feed