Statistical sampling plans are what you use when you're making thousands of cans of chili every hour, and trying to make sure there isn't too much ratmeat in the cans. Checking every can isn't really possible (perhaps somebody with a sensitive palate has to taste the chili for those subtle notes of squeaky meat), so what are you to do? Enter Statistical Sampling by Attributes, originally laid out in Mil-Std-105, and then updated in ASQ/ANSI Z1.4. Down below I've attached revision E of Mil-Std-105, which is the last revision in the public domain. Z1.4 revision (dash) could be considered revision F of Mil-Std-105

| mil-std-105e.pdf |

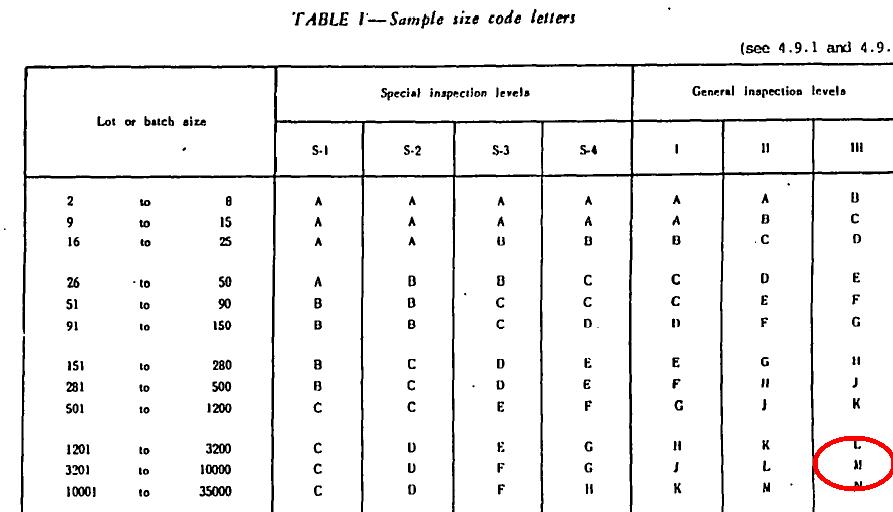

So you break open the Mil Standard, and start going through the steps. And by "steps", I mean the standard lays out, step by step, how to establish a sampling plan. We choose a verification level of 3, which is the most stringent, and decide to test batches of chili five thousand cans at a time. From Table 1, level 3 with 5,000 cans gives us Sample Size code M.

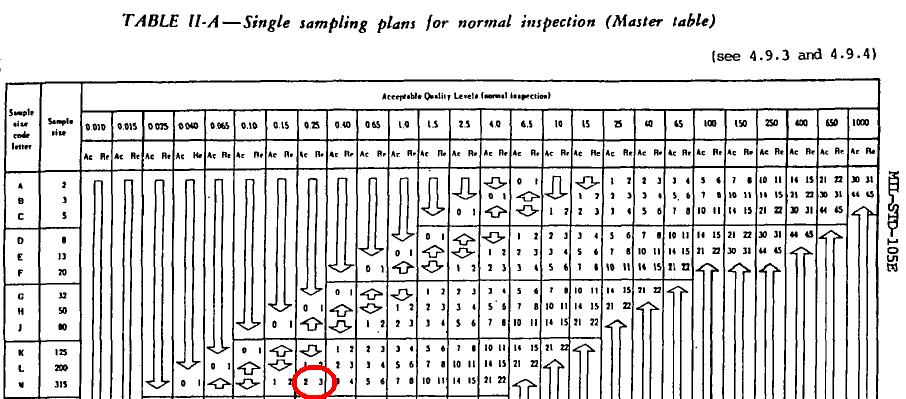

From there, we choose an Acceptable Quality Level of 0.25 (0.25% of cans can have ratmeat, because it won't actually kill the consumer), which by Table 2 means we will take 315 samples and will accept the whole batch as long as two or fewer samples are contaminated. We will reject the whole batch if three or more samples are contaminated.

If you're doing math along with me, you'll probably say "Hey, how does 2 in 315 get us to 0.25%?" And you'll be right that it doesn't. Not directly anyway. In table 5, the Average Outgoing Quality Limit for our inspection plan comes in at 0.44%, which means that if we test every complete batch of cans whose batch samples failed, and then throw away all the contaminated cans we find, we should have no more than 0.44% contaminated. This still isn't 0.25%...

The missing link is that the whole sampling plan is predicated on there being a quality control system that manages the inputs. In the case of our "rats in the chili" scenario, the quality control system would be a bunch of traps, or a herd of cats. For the sorts of applications the spec was written for, the quality control system would have been based on Mil-Q-9858. Like many older military standards, it's been replaced by a bunch of different industry standards (ISO 9001 for most applications, AS9100 for aerospace, ISO 13485 for medical devices, etc.)

The missing link is that the whole sampling plan is predicated on there being a quality control system that manages the inputs. In the case of our "rats in the chili" scenario, the quality control system would be a bunch of traps, or a herd of cats. For the sorts of applications the spec was written for, the quality control system would have been based on Mil-Q-9858. Like many older military standards, it's been replaced by a bunch of different industry standards (ISO 9001 for most applications, AS9100 for aerospace, ISO 13485 for medical devices, etc.)

So this is all good if you're the chili producer, and want to keep your chili relatively rat-free. But what if you're a grocery chain, and you don't make the chili yourself, but rather put your name on somebody else's chili? Accepting 2 in 315 won't get the chili factory to do their best job, and you don't know what the factory is doing to keep rats out.

What you can do is use a more stringent sampling plan, like what's described in Mil-Std-1916 "DoD Preferred Methods for Acceptance of Product". Mil-Std-1916 has the sort of sampling plan you might want if you were buying canned chili mac, and didn't have control over the chili factory itself. Essentially, start with all the sampling plans in Mil-Std-105, but only use the ones that reject the lots if there are any cans with ratmeat in them.

What you can do is use a more stringent sampling plan, like what's described in Mil-Std-1916 "DoD Preferred Methods for Acceptance of Product". Mil-Std-1916 has the sort of sampling plan you might want if you were buying canned chili mac, and didn't have control over the chili factory itself. Essentially, start with all the sampling plans in Mil-Std-105, but only use the ones that reject the lots if there are any cans with ratmeat in them.

RSS Feed

RSS Feed